Well, with the three day New Year's Day weekend looking like this outside,

I decided to fire up the woodstove in the shop and get started.

Here is what it looked like when I got the boat. It is a 2000 Ranger R83. It was owned by a couple in their 80's that liked to crappie and walleye fish. The boat is in perfect shape-not a single scratch on it or rock chip in the trailer. The only flaw was that he was a smoker and there were a lot of cigarette burns in the carpet.

I also just did not like the teal blue carpet.

Day one:

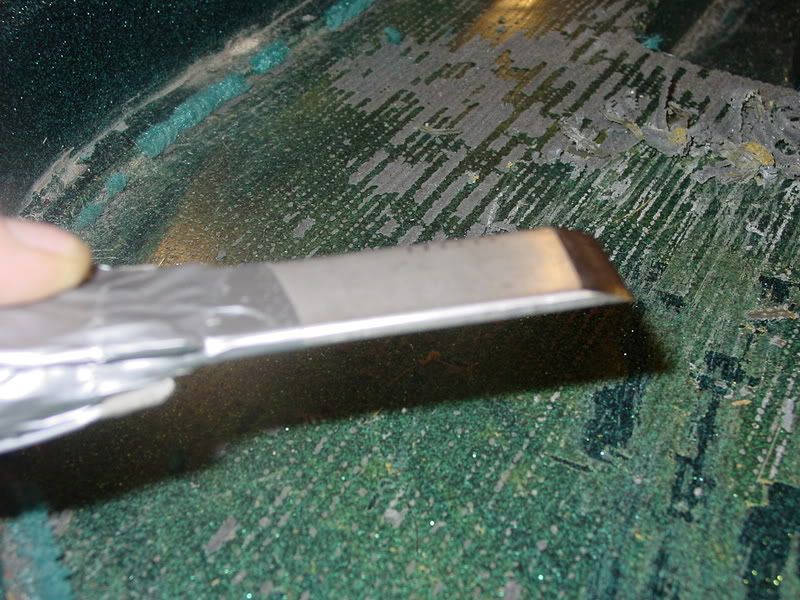

Pulled off all of the old carpet and started scraping the old backing and adhesive off of the boat. Everyone that has done this before has said that this is the worst part and I agree. I tried multiple tools, scrapers and putty knives, but they all flexed too much. So I took a piece of 1/8" x 1" stainless steel, sharpened it to a knife edge, wrapped one end in an old piece of carpet and duct tape and fashioned a small cushioned scraper.

It worked better than anything else I had tried. I would suggest and old wood chisel if you have one. It would hold an edge better. Even this one would last about 10-15 minutes, but a few strokes of the file to touch up the rolled edge and it was good as new. Keep it as sharp as possible and it works much better.

Day two:

Here is how it looked halway through day two:

I started carpeting the lids first. I ended up using both indoor/outdoor adhesive and contact cement. The carpet adhesive was used on flat suraces and large areas that I feared I might have to reposition the part. The lids were roughed out and glued flat and weighted with what we all have in the shop.

I then went to the front deck. It was laid with carpet adhesive and then trimmed to fit. As it went pretty well, I decided to tackle the floor. Once again, I did the outdoor adhesive and left all of the vertical areas clean.

Day three:

Tackeld the back deck. It was difficult, as there was so much cut out of the center, I dended up with an 8'x8' piece that had to be put in place. This would have been a good time to have two people. By rolling it up both ways to the center, I could put it down in the center and roll out both directions and the front side remained glue free.

After our recent discussion here: http://www.bbcboards.net...52264 I decided to take the time to close off part of the shop around the workbench so that I could work with the contact cement without risk of fire. Fumes were exhausted out the window. All of the lid edges were done with the contact cement.

I has been told that working with the contact cement was a pain and it was difficult to do the lid edges and get them to roll smoothly. What I did was precut all of the carpet. As it had already been glued to the top of the lids, I measured the height of the lid, the height of the inside lip, plus a 1/8" lid thickness and it cam out to exactly 2". so I took my carpenter's square, which is 2" wide, laid it up against the lid and pre-trimmed all of the flaps to 2"/ I then trimmed out the corners. It was them just a matter of painting bot hthe carpet and lid flange with contact cement, letting it dry and rolling the edges. I finished all of the lids as fast as I could paint them and dry them. All told, all lids were done in 2 hours.

Day four:

Finished the last batch of lids and started on the areas that were not completed on the decks and floor. Each was trimmed to fit, as they couldn't move because they were glued to the flat areas with carpet adhesive. I lucked out that it was warm enough in the shop to not have to start the stove, so I managed to finish all of the touch up contact cement work without fear of fire.

Day five:

Reattached all of the hinges and started to reinstall the lids.

Day six:

Everything came together. All of the final pieces went in. The center of the floor had a trim strip that went down each console and around the floor perimeter. It was pop-riveted on every 1 1/2" so it took a while to install. Finished the trim work around the front and back deck, reinstalled all of the switches and seat.

Here is the final product. All told, 55-60 hours, $50.00 of supplies and carpet that was included with the purchase of the boat.

Reply With Quote

Reply With Quote

Its like having a new boat when your done and the day after I finished mine I was on the water and been there 3 times this past week..I love having her back to fishing status again

Its like having a new boat when your done and the day after I finished mine I was on the water and been there 3 times this past week..I love having her back to fishing status again