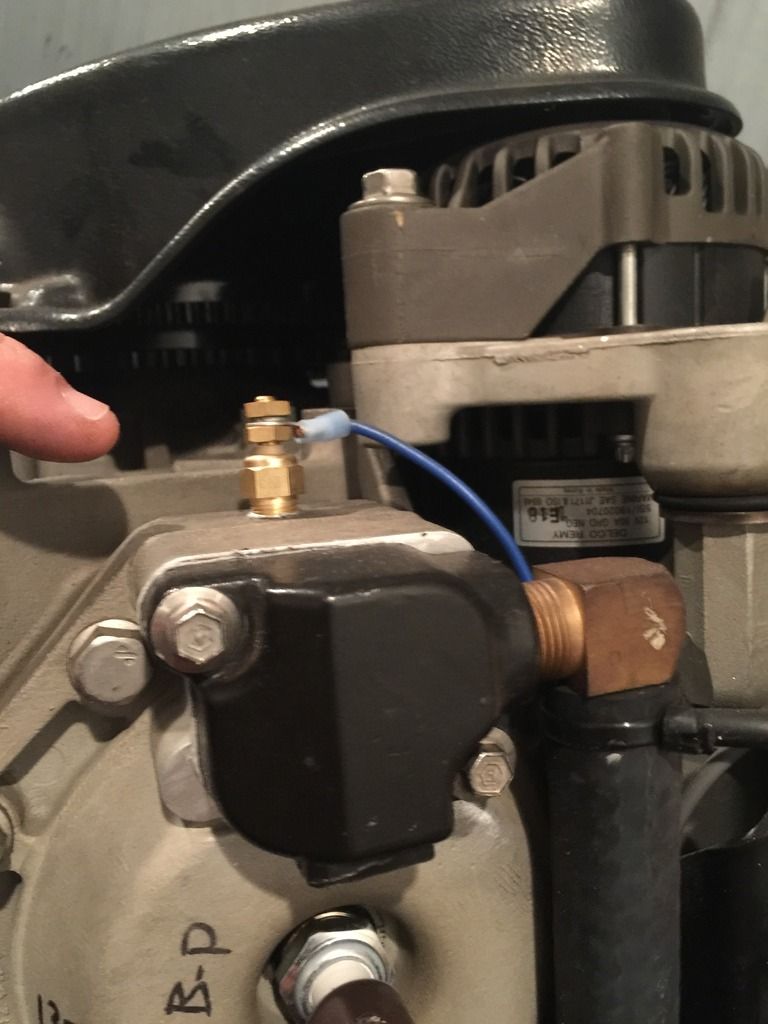

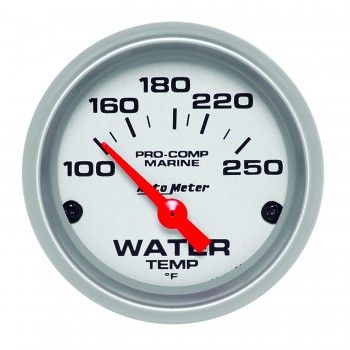

for the folks that want to read water temp for troubleshooting purposes or just to monitor temps, this can be done by drilling a hole and taping it just in front of thermostat, installing sending unit and installing gauge anywhere you want. make sure you use a teflon paste on the sending unit thread before you screw it in. most of your sending units are 1/8" npt thread(which is what mine is) and you use a 11/32 drill bit and a 1/8" pipe tap for the hole. You can also install a sending unit in each head and use the same gauge, just use an on/off/on switch to swap from one sending unit to the other, on the fly. User can also install a sending unit(s) and not install gauge but have gauge available when wanting to read temps when on the water hose. There is many different brand of gauges available whether it be digital or analog. temp ranges from 0-300+degrees. i used an autometer gauge Product # 200762-33. the sending unit is autometer also which isProduct # 990344. I wasnt to concerned with reading exact temp but more so if i have a problem which i figure i would see water temp rising rapidly but there is many different gauges available. a digital gauge would give the user an exact temp if thats what your looking for. they also start at a much lower temp sometimes as low as 0-300 degrees.

anyone that has questions about install and/or gauges thats available, ill be more than happy to help.

Reply With Quote

Reply With Quote