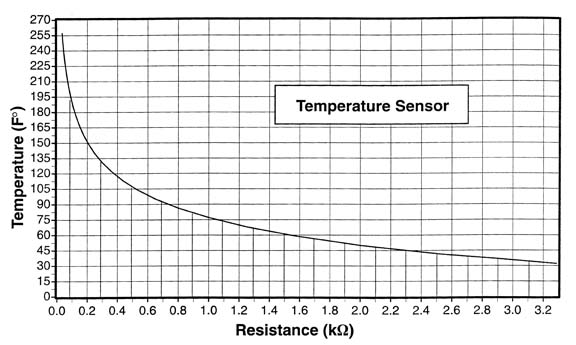

2000 Mercury 225 EFI, serial number 0T121338 on a Triton TR21. I have just rebuilt this engine over the winter and I have been fighting through some issues with it. New pistons, rings, bearings, seals, reeds (cages were lapped) injectors tested and serviced, new thermostats, plug wires, pulse pump rebuilt, you get the idea. I tried my best to rebuild anything that that was questionable as I want this to last a long time. Engine has ran well for the most part through the breakin period, but all at once it really started to run poorly. The last issue turned out to be a failed CDM on cylinder #6, causing #2, #4, #6 to run poorly, foul plugs and the engine to have low power. Replaced coil, also added extra ground wires for ECMS and CDM s as I read that they can be an issue as well, back up and running fairly well, but I noticed it smelled like fuel and I still thought smoething just felt "off". Got home and checked for leaks and could not find anything. Next trip out it was back to being a pig, struggled to get on plane and would only run 64 MPH as opposed to the normal 68-70. It also idled a little rough with the occasional stutter or misfire. Changed and gapped spark plugs, this was no help. Still smelled like gas badly. Brought it home, trimmed engine down in the garage to drain and let it set a couple of days. When I went back to work on it I noticed an oily fuel/oil mixture that had drained onto the floor, appeared to have come from the intake area and ran down a wire harness for the trim motor. I suspected a possible reed issue, so I pulled the intake manifold loose to inspect the reeds. Reeds look great, no issues, but I did find what I thought was an usual amount of oil and gas pooled up in the intake, mainly around cylinders 3 and 4 reeds and in the bottom. I cleaned this out and reinstalled the intake. Put my pressure gauge on the fuel rail and turned the key to the on position. It was 40 PSI, so I let pump finish cylcling and turn off and watch the gauge to make sure it was holding pressure. It appears to be fine, no visual leaks looking through the butterlies and held pressure for roughly 5 minutes before slowly going down. After 10 minutes it was down to 34PSI. I am thinking this is not my issue, so I removed the thermostats and verified that they are working properly and not stuck, and hot water tested them. Check good, 143 degree stats. I have tested the stator, cylinder head temp sensor, IAT sensor, and MAP sensor with an OHM meter using the specs from the manual. Ran on the engine on the hose while in a tank and verified all of my cylinders are firing with the timing light. TPS is set to .98 volts. I am just not finding anything unusal that ican say is the issue. I have been running my stock pair of ignition and fuel ecm's as I am no longer running my shaved heads, and have went back to stock heads on this engine. Just for the hell of it I put my other pair of ECM's which are flashed to 300 PM spec and took it to the lake for a test run. It ran much better! Holeshot was back, it ran 67-68 on the GPS. I ran it around for about 15 minutes. When I shut it down to put it back on the trailer I noticed the gas smell is still very heavy, and it appears to be just dumping to much fuel. I think the "hotter" ignition from the 300 PM ECU just maksed my problem. So, I know I took the long road to get here, but my question is...what am I missing here? What could be causing this engine to over fuel like this? I am still running the oil injection on this engine as well. Any help would be appreciated, thank you in advance. It is also drinking gas like 900 HP Chevy big block! lol

Reply With Quote

Reply With Quote